Outsourced Assembly Services for Regulated Medical Equipment

PEKO provides medical device assembly services for OEMs building complex capital equipment, diagnostic machines, laboratory systems, and other medical technology. We support programs that require thousands of hours of cleanroom, mechanical, and electromechanical assembly work per year, under strict quality control and documentation.

PEKO’s Role in Medical Device Assembly

PEKO serves as a medical device assembly contract manufacturing partner for OEMs that design and sell regulated medical equipment. We do not develop devices ourselves—we focus on manufacturing the product and integrating components based on your drawings and documentation.

Our capabilities span:

- ISO 13485-certified quality system

- Cleanroom and clean-adjacent assembly spaces

- Complex mechanical and electromechanical integration

- Product traceability, serial labeling, and testing

- Custom packaging and discreet logistics

Why Leading Medical Device OEMs Choose PEKO

- ISO 13485 Certified — Our facilities and processes meet the standard for quality management in regulated medical manufacturing.

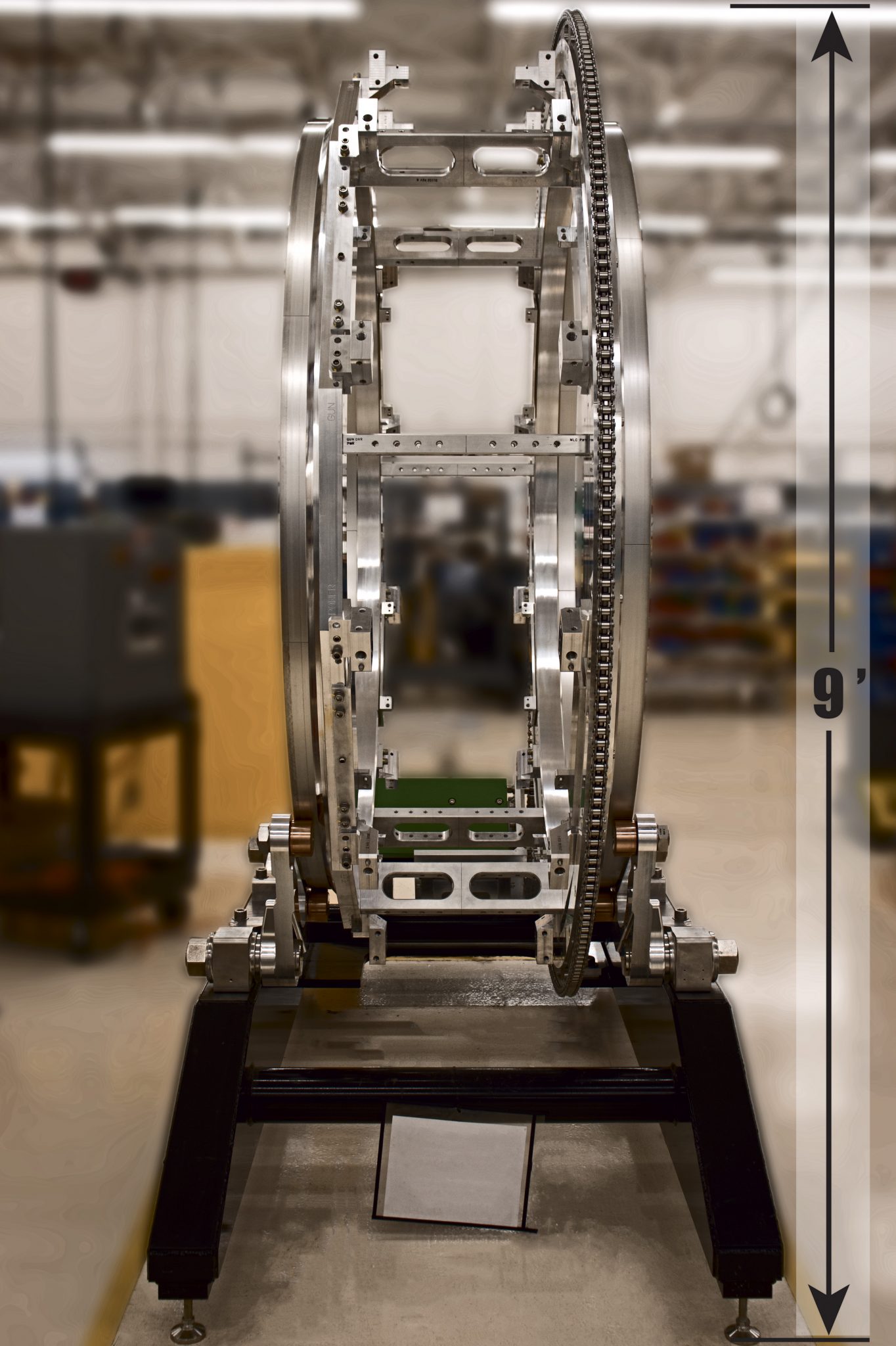

- Subsystem and System-Level Assembly — We build not just components, but full subsystems, enclosures, and functional units that integrate into your top-level product.

- Program-Based Manufacturing — PEKO supports medical device assembly production programs that involve thousands of assembly hours per year—not small-batch builds or commodity-level parts.

- Controlled Assembly Environment — We have cleanroom assembly and white-room areas to support contamination-sensitive equipment and modules.

- Engineering Collaboration — We assist with fixture design, build documentation, layout planning, and test protocol integration.

Typical Medical Device Assemblies We Support

- Electromechanical diagnostic machines

- Modular enclosures for medical and laboratory equipment

- Instrument frames, panel kits, and cart assemblies

- Motion system subassemblies with wiring and controls

- Component integration: pumps, valves, sensors, fans, PCBs

What’s Included in PEKO’s Medical Device Assembly Services?

- Component Sourcing & Inventory Management

- Mechanical and Electrical Assembly

- Cleanroom or Clean-Adjacent Build Environment

- Work Instructions, Travelers, & Traceability

- Labeling, Serialization, & Compliance Documentation

- Functional Testing per Customer Specs

- Custom Packaging and UDI Labeling (if required)

Let’s Build Medical Equipment Together

If you are an OEM seeking a domestic partner to support complex medical device assembly, PEKO is ready to help. Our vertically integrated approach and deep assembly experience help reduce your vendor count, improve build quality, and support your program for the long haul.