Subsystem & Equipment Assembly for Military & Defense-Related OEMs

PEKO provides defense assembly services for DoD prime contractors and OEMs building ruggedized systems, mission-critical subsystems, and electromechanical enclosures for U.S. defense programs. We specialize in high-mix, low-to-medium volume builds that demand traceability, process control, and long-term program support.

Built for Military and Defense Applications

PEKO is a U.S.-based manufacturing partner that supports the defense industry with:

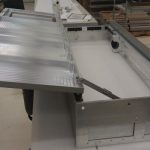

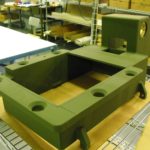

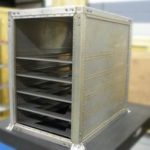

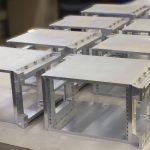

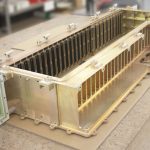

- Ruggedized sheet metal enclosures & chassis

- Electromechanical subsystems with motion & control

- Cleanroom-compatible & sealed assemblies

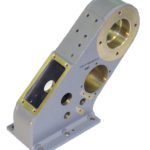

- Precision-machined frames, brackets, & armor panels

- Full documentation, serialization, & data retention

Our teams build to spec and integrate customer-furnished components into secure, testable builds.

Defense Assembly Services Include:

- In-House Part Fabrication – We manufacture CNC machined and sheet metal components ready for assembly under our AS9100-certified quality management system.

- Mechanical & Electromechanical Assembly – Installing specialized rivets, PEM fasteners, and custom brackets using torque-limiting tools, jigs, and military-compliant joining techniques.

- Wire Harness & Terminal Block Installation – Routing multi-branch harnesses, secure strain reliefs, EMI shielding, and custom lacing and bundling per defense specs.

- Power Routing & Cable Management – Integrating connectors, ferrites, terminal blocks, and redundant paths for high-reliability performance in mission-critical systems.

- Shock & Vibration-Tolerant Build Techniques – Applying isolation mounts, reinforced bracketing, foam supports, and ruggedized enclosures for ground and mobile systems.

- MIL-STD Packaging & Foam Crating – Custom-cut foam, anti-static bags, desiccants, and compliant documentation for secure shipment and staging.

- Secure Logistics & Discreet Fulfillment – Domestic-only routing, white-label options, and tracking methods that meet sensitive delivery and traceability requirements.

Defense Applications & Assembly Program Types

We build defense assemblies for:

- Ground systems & ruggedized field equipment

- Weapons testing & diagnostic machinery

- Aircraft subsystems & flight hardware enclosures

- Sensor housings & pod assemblies

- Tactical control systems & interface panels

Why OEMs Choose PEKO for Defense Assembly

- CMMC Cybersecurity Compliance → PEKO maintains strong data protection and information handling practices to support defense customers under the Cybersecurity Maturity Model Certification framework

- Vertically Integrated Manufacturing → In-house sheet metal, CNC machining, coating, and inspection capabilities

- Controlled Assembly Environments → Clean areas for contamination-sensitive defense components

- Defense-Experienced Workforce → Cross-trained technicians and program managers familiar with ITAR, DFARS, and program-based manufacturing

- Subsystem & System-Level Builds → From power enclosures to sensor pods and electromechanical motion assemblies

- U.S.-Based Supply Chain Security → All work performed in Rochester, NY with complete domestic oversight

Start Your Defense Assembly Program Today

PEKO is an ideal partner for OEMs looking to outsource ruggedized subsystem builds in compliance with U.S. defense program requirements. We work under NDA, build to print, and support long-term programs with dedicated manufacturing cells and experienced program managers.