High Precision Component Assembly

When your systems demand exacting tolerances and flawless integration, PEKO delivers. Our high precision assembly services are engineered for complex electromechanical systems and components that require tight tolerances, expert handling, strict quality controls, and uncompromising accuracy.

- Precision assembly tailored to customer specs

- Tight tolerance capabilities down to microns

- ESD-safe & cleanroom-compatible assembly areas

- Optics, motion, robotics, & sensor integration

- AS9100, ISO 13485, & ISO 9001 certified processes

- Fully traceable quality documentation & testing

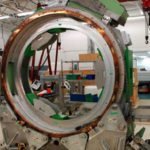

What Is High Precision Assembly?

High precision assembly involves the integration of sensitive, high-tolerance components into fully functional systems. These assemblies often involve mechanical structures, electronics, optics, sensors, and motion controls—all requiring exact alignment and precise handling.

Why It Matters:

- Reduces risk of misalignment & premature wear

- Improves product reliability & service life

- Eliminates rework & costly delays

- Ensures consistent quality with every unit

Solving the Core Challenges of Outsourced Precision Assembly

Outsourcing precision assembly often comes with headaches—unreliable vendors, quality inconsistencies, supply chain delays, and integration issues. At PEKO, we solve these challenges by offering a complete, in-house approach to high-tolerance, complex assemblies.

Here’s how we address the challenges that other vendors can’t:

- Limited True Precision Assembly Expertise → Many vendors claim precision capabilities but struggle with high-tolerance, multi-component builds. At PEKO, precision is our specialty. Our engineering-led approach and skilled technicians deliver consistent, high-accuracy assemblies—backed by decades of experience and industry certifications.

- Quality Inconsistencies & Tolerance Stack-Up → When different vendors handle machining and assembly, mismatched parts can cause fit-up issues and system failures. PEKO controls both machining and assembly under one roof, ensuring component compatibility, seamless integration, and consistent build quality.

- Complex, Fragmented Supply Chains → Managing multiple suppliers for machining, electrical integration, and testing adds cost, risk, and lead time. PEKO’s vertically integrated facilities combines all services in-house, streamlining your supply chain to eliminate the need for multiple purchase orders, material receipts, and quality checks.

- Lack of Collaborative Engineering Support → Many vendors stick to a rigid build-to-print model and miss opportunities for process improvement. PEKO offers DFMA and engineering assistance, collaborating with you to optimize component layouts, reduce part count, minimize costs, improve assembly processes, and support production scalability.

What Sets PEKO Apart?

At PEKO, precision is more than a standard—it’s a promise. Our Precision Assembly Services are built on advanced alignment technology, stringent quality controls, and years of specialized expertise to ensure your components are assembled with unmatched accuracy.

- Controlled Assembly Environments: Our clean, climate-controlled assembly areas are designed to protect sensitive components and maintain critical tolerances during the build process.

- Expert Technicians & Specialized Tooling: Skilled professionals, equipped with calibrated tools and precision fixtures, ensure exact fits and repeatable outcomes for every build.

- Vertically Integrated Manufacturing: In-house CNC machining, sheet metal fabrication, and wire EDM capabilities ensure all components are precisely fabricated before assembly begins.

- Precision Assembly & Alignment: Utilizing custom fixtures and advanced alignment tools, we guarantee exact component placement and tight tolerances throughout the assembly process.

- Advanced Testing & Verification: Every assembly is verified using dimensional inspection, functional testing, and performance validation, guaranteeing reliability and compliance.

- Engineering-Driven Processes: From work instructions to quality checkpoints, our engineers oversee the entire process to ensure consistency, scalability, and traceability.

- Compliance & Certification: We meet or exceed rigorous industry standards including AS9100, ISO 13485, and ISO 9001, providing peace of mind for OEMs in regulated markets.

- End-to-End Program Management: We manage every aspect of your precision assembly project, from part management and sourcing to packaging, warehousing, and shipping.

Built for High-Stakes Industries

Our precision assembly solutions are tailored for systems that demand reliability, precision, and durability—ensuring optimal performance in critical applications.

- Aerospace & Defense Systems

- Medical Diagnostics & Imaging

- Scientific Instruments

- Robotics & Motion Control Systems

- Semiconductor & Clean Tech Equipment

Precision Assembly You Can Count On

If your systems require exacting standards and zero margin for error, PEKO is the precision assembly partner you need. Our advanced capabilities, experienced staff, and commitment to quality make us a top choice for OEMs in critical industries.

Request a quote or schedule a consultation today to discover how PEKO can deliver precision-built assemblies that meet your exacting standards.