Contract Electrical Assembly & Integration Services

Expert Support for Advanced Electromechanical Systems

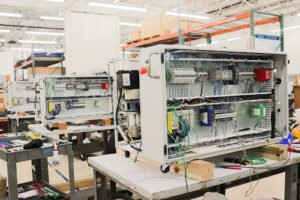

At PEKO, electrical assembly is a critical component of our vertically integrated contract manufacturing services. With decades of experience in complex machinery and electromechanical platforms, we specialize in building custom electrical assemblies that are engineered to align seamlessly with your full system requirements. Leveraging extensive expertise, our skilled technicians assemble and coordinate wiring, cable harnesses, control panels, box builds, electronic devices, and subassemblies, ensuring optimal operational performance and long-term reliability.

- Full-system electrical integration for complex mechanical assemblies

- Precision wiring, panel assembly, and custom enclosure builds

- Ensuring seamless connectivity within multi-component assemblies

- Built-in compliance with IPC, UL, and ISO manufacturing standards

A Key Component of Turnkey Contract Manufacturing Solutions

At PEKO, electrical assembly is more than just a step in the process—it’s a foundational element of our turnkey machinery and assembly manufacturing solutions. Our in-house team of skilled electricians ensures that every component is precisely placed, cleanly wired, and fully functional—ready to be integrated directly into larger, more complex mechanical and electromechanical assemblies right here on-site.

- Designed for System-Level Integration → Our electrical assembly services are tailored to support complex electromechanical builds, ensuring seamless compatibility across the entire system and a cohesive, reliable final product.

- Customized to Fit Larger Builds → Rather than standalone products, these solutions enhance the performance of our top-level machinery and high-level assembly contract manufacturing programs.

- Optimized for Reliability & Functionality → Each wire, panel, enclosure, and subsystem is designed to meet the demands of the full assembly, delivering dependable performance under real-world operating conditions.

An Inside Look: Our Electrical Assembly Process at PEKO

From concept to completion, our team works collaboratively with your engineers and stakeholders to ensure a smooth integration process—delivering fully assembled, fully tested, and installation-ready electrical systems that work in perfect harmony with your mechanical and electromechanical builds.

- Collaboration with Design & Engineering Teams → We work closely with you to ensure every electrical component is planned, placed, and built to fit seamlessly into the mechanical layout and overall assembly.

- Precision Wiring & Electrical Panel Assembly → We build custom wiring harnesses, control panels, and electrical subsystems designed for direct integration into mechanical enclosures and larger system builds.

- Testing & Verification for System Compatibility → Every integrated assembly undergoes rigorous testing to confirm electrical functionality aligns with mechanical performance needs—ensuring total system reliability.

- End-to-End Assembly & Delivery → We manage every stage of integration to deliver complete, tested assemblies ready for final system installation—minimizing onsite setup and maximizing deployment efficiency.

Our Electrical Assembly & Integration Capabilities

Our comprehensive electrical assembly capabilities deliver seamless integration of complex electrical systems, components, and technologies to create fully functional electromechanical assemblies tailored to your project requirements.

-

Schematic & Diagram Interpretation

- Reading and interpreting electrical schematics, wiring diagrams, blueprints, specifications, work orders, and technical reports.

- Determining material requirements, component placement, assembly and wiring sequences, and proper electrical interconnections.

- Supporting pre-assembly planning and layout for maximum efficiency and compliance.

-

Wire Preparation, Routing & Installation

- Cutting, stripping, crimping, labeling, bundling, and terminating wires to meet precise length and connection requirements.

- Assembling custom cable and wire harnesses for optimized electrical performance and installation efficiency.

- Strategically routing wires and cable harnesses through frame constructions, back panels, and enclosures to the appropriate components.

-

Component Placement & Integration

- Mechanical-to-electrical interfacing and turnkey electrical system integration, including integration of hydraulics and pneumatics.

- Integrating electrical components into back panels, DIN rails, control boxes, subassemblies, and chassis.

- Installing integrated PDUs, control systems, automation interfaces, sensors, motors, drives, controllers, and safety mechanisms.

- Point-to-point wiring from panel connections to corresponding field devices and machine-mounted components.

- High-quality soldering and brazing of electrical joints for robust, reliable electrical connections and long-term durability.

- Implementing ESD protection and control measures to safeguard sensitive components during assembly, including bonding and grounding.

-

Inspection, Testing & Troubleshooting

- In-process and final inspections to validate workmanship, electrical performance, and mechanical integrity.

- Functional testing of completed assemblies and subsystems using multimeters, continuity testers, and simulation tools.

- High-pot, insulation resistance, and dielectric strength testing when required.

- Troubleshoot and debug of electrical systems as needed, including rewiring, rework, and firmware/hardware interface checks.

- All testing and inspections conducted in accordance with UL, IPC/WHMA-A-620, and ISO 9001 standards.

-

Documentation, Traceability & Quality

- Comprehensive documentation of as-built assemblies and electrical systems, wiring updates, and configuration changes.

- Bill of Materials (BOM) verification and schematic alignment throughout the build process.

- Complete traceability of components and materials used, supporting customer audits and compliance requirements.

- Continuous quality improvement and adherence to internal and customer-specific QA protocols.

-

Value-Added Electrical Assembly Services

-

In-House Custom Metal Manufacturing

We have internal CNC machining, sheet metal fabrication, and welding capabilities for producing the precision-engineered enclosures, cabinets, racks, chassis, and other structural and mechanical components needed to securely and efficiently mount and house your electronic assemblies. Our expertise in managing both the mechanical and electrical manufacturing aspects of your project in-house guarantees seamless integration of electromechanical assemblies with high-quality, precision-fit parts that meet your exact specifications and enhance the performance of your products.

-

DFM Analysis & Engineering Support

Our electrical engineering team works closely with your design and product development teams, supporting electrical assembly programs with DFM analysis, value engineering, and reverse engineering. Whether improving existing designs or replicating legacy systems, we help you design electrical assemblies that are functional, cost-effective, and optimized for manufacturability. We also provide retrofitting services, ensuring your products remain up to date with the latest technologies and meet industry standards.

-

New Product Introduction & Prototyping

When you’re launching a new device, we offer development and prototyping services that cater to the unique requirements of electrical assembly. With a focus on complex electrical assemblies and electromechanical systems, we produce functional prototypes of your design for testing and iterative refinement. Our team works hand-in-hand with you to choose and integrate the right electrical components while expertly managing complex wiring and pneumatic systems to ensure your design is optimized for real-world performance before committing to full-scale production.

-

Manufacturing Documentation Development

Our team of electricians work closely with our engineering and manufacturing teams to develop production-ready documentation packages, including detailed electrical schematics, wiring diagrams, blueprints, and build matrices to ensure consistency across all stages of production. Additionally, we provide work instructions and real-time updates to keep your documentation current as designs evolve or changes are made. This documentation ensures that each assembly is built to specification and can be easily reproduced at any scale.

-

Supply Chain Management & Logistics

We help manage every aspect of your supply chain, ensuring all components, machine controls, and materials for your electrical systems arrive on time and meet your specifications. Our strategic sourcing process includes procuring both COTS and custom components for your electrical assemblies. We handle everything from vendor selection to logistics, ensuring just-in-time deliveries that perfectly align with your production schedule. This allows you to focus on your core operations while we take care of the complexities of sourcing and inventory management.

-

Types of Electrical Components We Integrate

When it comes to electromechanical products, we can assist with most aspects of electrical assembly. Our electricians specialize in installing and configuring a wide range of electrical and power distribution components into industrial enclosures, control panels, and box builds, including:

- Programmable Logic Controllers (PLCs) – Allen-Bradley, Siemens, Schneider Electric, Mitsubishi, Omron

- Power Distribution Units (PDUs) – Eaton, ABB, Schneider Electric, General Electric

- Motor Control Centers (MCCs) & Drives – Rockwell Automation, Yaskawa, Danfoss, WEG

- Human-Machine Interfaces (HMIs) & Operator Panels – Siemens, Beckhoff, Red Lion

- Relays, Contactors & Circuit Protection Devices – Phoenix Contact, Weidmüller, Eaton, ABB

We ensure these electrical components are seamlessly integrated into larger mechanical assemblies, delivering complete electromechanical assembly and system builds that align with our customers’ specifications and comply with all applicable electrical codes and industry standards.

Common Types of Electrical Assemblies We Build

Whether you need a fully wired cabinet, a custom control box, or a complete turnkey system, you can trust us to deliver production-ready solutions that are engineered to perform.

We have experience assembling:

- Control Systems: custom control boxes, electrical control panels, and power distribution units (PDUs)

- Power & Signal Management: power supply assemblies, switch and sensor integration, and DIN rail builds

- Panel & Enclosure Wiring: back panels, sub-panels, front panels, chassis, racking systems, and busbar assemblies

- Custom Enclosures & Cabinets: custom electrical enclosures and industrial electrical cabinets

- Box Build Integration: full box builds and complete panel wiring and assembly

- Modular & Sub-Assembly Units: pre-configured electrical sub-assemblies and wiring modules

- System-Level Solutions: electromechanical assemblies, higher-level assembly (HLA), and turnkey systems

Industries & Applications We Support

We take great pride in helping OEMs and innovators across a variety of high-tech industries bring their complex electromechanical systems to life. Our electrical assembly services are designed to support the most advanced industrial, technological, and mission-critical applications. Whether you’re building industrial machinery, automation systems, or advanced electromechanical devices, our experts ensure every electrical connection is precisely installed, thoroughly tested, and aligned with the performance of your overall system.

We provide scalable solutions for:

- Industrial Automation Machinery: Integrated control systems, wiring harnesses, and panel assemblies for complex manufacturing equipment, robotics, and material handling systems.

- Medical Technology & Equipment: Precision electrical assemblies for medical imaging systems, diagnostic instruments, and patient monitoring systems.

- Defense & Aerospace Systems: High-reliability assemblies for ruggedized platforms, radar systems, ground support equipment, and secure communication consoles.

- Semiconductor Equipment: Electrical panel builds and wire routing for tools used in semiconductor fabrication and high-purity processing.

- Telecommunications Systems: Assembly of power distribution units, network enclosures, and signal management systems for high-performance communications infrastructure.

- Energy & Power Systems: Electrical integration for renewable energy, power management, and battery storage technologies—including busbars, inverter wiring, and control panel assemblies.

- Laboratory & Test Equipment: Custom wiring and control systems integrated into lab automation platforms, metrology tools, and test stands.

- Custom OEM Equipment: Full-system electrical integration of complex, one-of-a-kind machinery built to spec—including electromechanical subsystems, sensors, and automation controls.

Our cross-functional expertise ensures every assembly meets performance standards, environmental specifications, and industry compliance requirements such as UL, IPC-A-620, and ISO.

Advantages of Choosing PEKO for Electrical Assembly

- Full in-house electrical capabilities—from wire prep and panel assembly to final testing

- On-site fabrication and welding of sheet metal enclosures, panels, frames, and structures

- ISO-certified assembly processes and compliance with key industry standards

- Scalable production from prototype to full-volume production

- Proven success across regulated and high-performance industries

- Hands-on collaboration to refine and optimize your electrical designs

Let’s Build Together

Whether you need I/O wiring, signal conditioning, board interconnections, chassis wiring, or other electrical assembly services, look no further than PEKO. We thrive on complexity and have the knowledge and experience to handle complex electrical integrations with precision and efficiency. Contact us to discuss your unique electrical assembly challenges and how we can help.