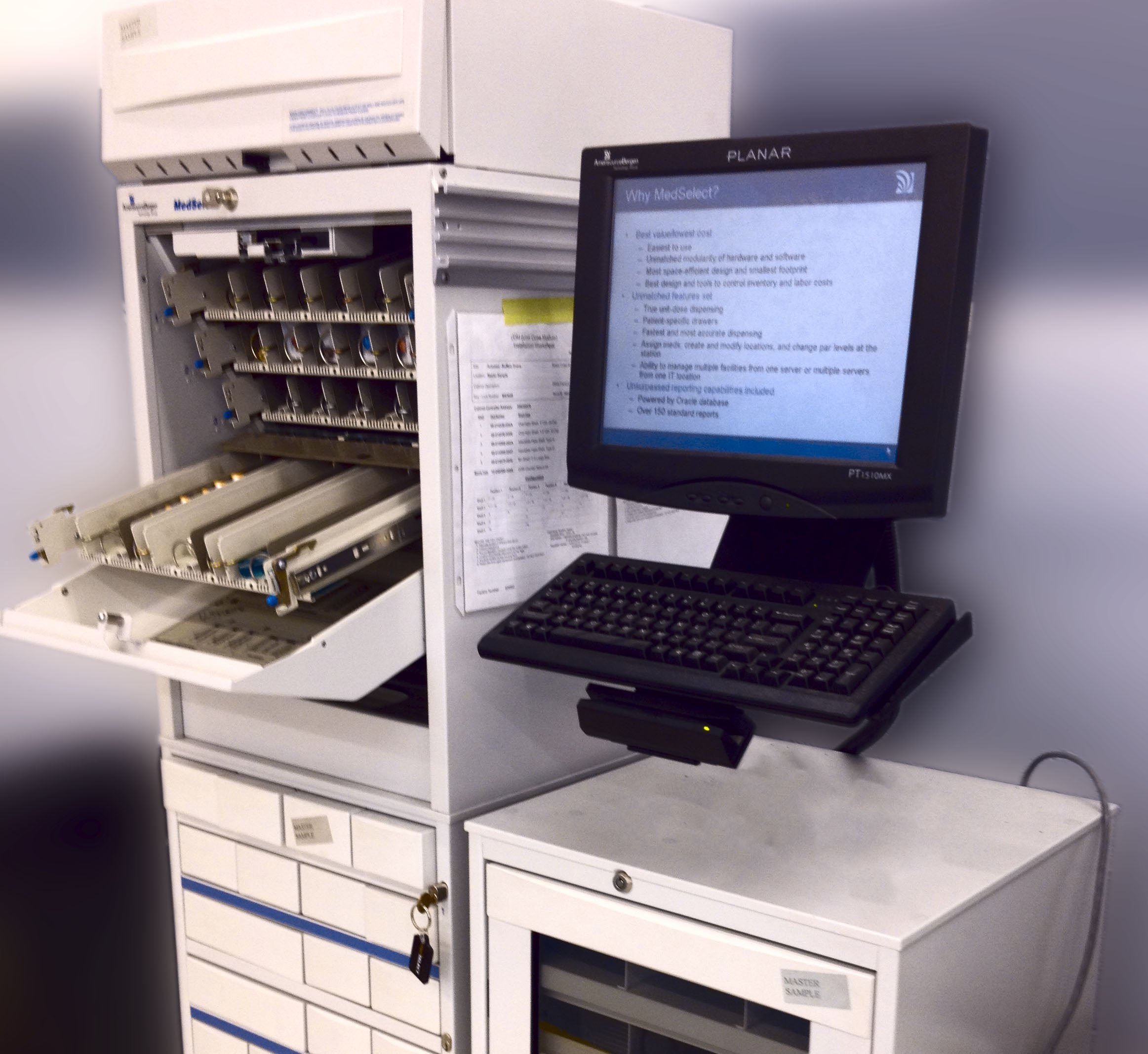

Automated Dispensing Cabinet for Pharmaceutical Company

Challenge

A leading provider of pharmaceutical technology solutions had identified significant gaps in functionality and scalability of their current automated dispensing cabinet (ADC) and medical inventory management system offering. The most significant shortcoming of their existing ADC design was that it did not allow for a direct drop-in field replacement to their largest competitor’s offering.

To remain competitive, the company identified some new features and functionality that it would like to incorporate into the next generation of the automated dispensing cabinet’s design, some of which the required technology had not yet been fully developed. With expected production volumes of 100s per year, the current lead times for customized configurations of the redesigned medical dispensing machine from their current contract manufacturer, a multi-billion-dollar entity, were unacceptable.

In order to reach its goals, the company was challenged with finding an ISO 13485 contract manufacturer with the expertise, capability, and capacity to redesign and manufacture the complex electromechanical system.

Solution

The pharmaceutical giant chose PEKO as its manufacturing arm due to our expertise in electromechanical engineering and manufacturing for the medical industry and its familiarity with the requirements this system entailed. PEKO’s versatile “toolbox” of capabilities and resources provided the Customer with a single partner to accomplish the extensive list of product development requests and redesign requirements.

At launch, PEKO assigned a program manager to the account to provide a dedicated customer service point of contact for the customer. A manufacturing team was then assembled and briefed on the program and began the task of transferring the part and purchase information into PEKO’s manufacturing system.

While the automated dispensing cabinet was highly complex in its mechanical and electromechanical design, the program manager and manufacturing team set out to reduce assembly times while also allowing for product configurability. Throughout the development process, extensive testing and FMEAs were completed to comply with stringent medical product code requirements. Design changes to improve manufacturability and reduce lead time were also implemented.

SUccess

PEKO’s method of product adoption and comprehensive onboarding process ensured that the program was easily transferred from the previous manufacturer without any interruption to the customer’s business or supply chain.

PEKO successfully manufactured the as-received automated dispensing cabinet product line, and then went on to design and build the next generation of the product using market research and manufacturability improvements. A modular and scalable medical dispensing machine was created to ensure the final end-user was able to order exactly what they needed, and the subsequent assembly time was driven down to 5 days.

The customer received the functional product results and production lead times desired, and the new system provided additional value to end-users and further drove the customer’s sales.

Get in touch with us today to see how PEKO Precision can meet the needs of your project.