PEKO can assist you in the engineering, development, and integration of any custom PLC programming you need to control your automation manufacturing equipment, industrial processes, and control systems.

Alongside our custom machine building services, PEKO is proud to offer top-tier PLC programming services that help elevate your automation capabilities and streamline your operations. Our engineers can assist you in developing, programming, and integrating new PLC-based control systems from scratch and troubleshooting, updating, or expanding PLC programs on existing machines as needed.

The Importance of PLCs in Industrial Automation

Programmable Logic Controllers (PLCs) have become the backbone of modern industrial automation, serving as the foundation for developing complex control systems that are tailored to specific applications. They are common in most advanced control systems today and are utilized in a diverse array of sectors, such as manufacturing, oil and gas, water treatment, and more. They serve as the brains of your machine, translating varied and complex operational requirements into precise, efficient instructions and can be used to control everything from simple on/off functions to complex motion control and data processing tasks.

Because of the critical functions they perform, effective PLC programming and integration is key to a successful automation system. But with their proprietary programming language and complex logic structure, it is not a task for the faint of heart. This process requires specialized knowledge, meticulous planning, and careful execution for optimal, efficient, and accurate system performance.

Getting your PLC programmed by skilled professionals, like PEKO, can help you realize its full potential in your operations. We have a proven track record and long history of success developing PLC automation solutions for diverse electromechanical systems, industrial and automation processes, and custom machine builds. This extensive experience gives us an in-depth understanding of process improvement and the individual needs of each machine type or industry niche.

We’ve worked with some of the biggest names in manufacturing across a wealth of high-tech industries to provide reliable PLC programming services that keep their automated systems connected and running smoothly. We’ve helped countless clients achieve increased production efficiency, reduced operational costs, improved product quality, enhanced safety protocols, and greater system flexibility.

PLC Programming Solutions for Your Custom Automation Needs

Whether you need custom PLC programming services for simple automation or a complex system for advanced applications, you can trust we will deliver solutions that control your automated processes with the utmost reliability and help you stay competitive in an evolving industrial landscape. Our controls engineering team is skilled in all aspects of PLC programming, including hardware selection, schematic creation, control panel build, systems integration, testing, and troubleshooting, allowing us to provide complete, turnkey solutions for our clients’ custom automation equipment manufacturing needs.

Custom PLC Programming & Installation

Custom PLC Programming & Installation

At PEKO, we perform custom PLC programming on most machinery, equipment, and hardware we manufacture for our OEM and custom machine builder customers. No matter the kind or type required, we have the expertise to program the logic that allows PLCs to be seamlessly integrated in your new or existing equipment design.

Our team of controls technicians are adept in a broad spectrum of PLC platforms and major programming languages, like ladder logic. We excel in working with renowned platforms such as Allen-Bradley, Siemens, Beckhoff, Delta Tau, and OMRON, among others. We also have expertise that extends to most other PLC brands, programming environments, and processors commonly used today, guaranteeing the flawless integration of cutting-edge features into your machine design.

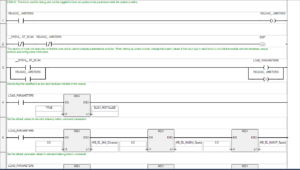

Our programs are meticulously structured and extensively documented to ensure optimal efficiency and reliability. By utilizing modular PLC code, we have created a streamlined and flexible framework that is not only easier to understand, debug, and modify but also complies with all applicable industrial and software standards. We also perform any necessary testing and debugging to ensure that everything is working properly before it leaves our facility.

PLC Engineering & Hardware Selection

In case your PLC control panel hasn’t yet been specified, our PLC engineering experts will work closely with you to understand your applications requirements and recommend well-suited control protocols and solutions optimized for your unique automated processing needs. We then collaborate with you to develop and implement custom PLC programming that incorporates the logic, functions, and control requirements specified and create detailed schematics and control panel layouts, as required.

Backed by years of experience in PLC engineering, our team is prepared to manage a broad spectrum of applications, including machine control, process control, material handling, pump control, quality control, and more. From specifying the right hardware to creating custom programs, we assist you every step of the way.

We possess in-depth knowledge of diverse features, industries, compatibilities, and use cases of various PLC types and brands available in the market. This expertise ensures we identify the best solution for your application and can effectively fulfill any requirement you may have.

PLC Integration & Turnkey Control Systems

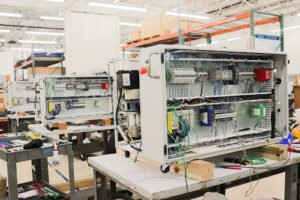

We aim to go far beyond mere specifying PLCs and coding programs, putting our deep understanding of industrial processes and cutting-edge programming techniques together to develop vertically integrated turnkey solutions to your target specifications. Our electrical controls assembly team can help you bring together the hardware, software, and control logic needed to implement efficient and effective PLC-based control systems and electrical control panel assemblies to completion.

We offer all the necessary resources to wire, test, and verify designs in-house to complete wire assemblies and top-level integrations of your custom automation equipment. We have experience integrating PLCs with a range of other automated systems and machine control technologies, like VFDs, SCADA software, HMI displays, sensors, actuators, and more. When combined with our automated systems engineering expertise and vast in-house contract manufacturing and assembly services, we are able to deliver full-service solutions for our customers’ turnkey custom automation equipment needs.

Whether you need a few prototypes or hundreds of production units, we can handle it. We’ve successfully completed PLC integration into projects of all sizes and work closely with clients throughout the entire process, ensuring that their needs and requirements are met every step of the way.

Why Choose PEKO for Your PLC Programming Services?

With decades of experience in the science of custom machine building and control system engineering, PEKO’s dedicated and experienced team has both the specialized expertise and machine-specific knowledge needed to tackle your most complex automation challenges. Our custom PLC programming services are supported by a team of expert controls engineers, industrial programmers, software engineers, qualified technicians, and certified electricians who are well-versed in handling complex, PLC-based control system applications.

- Customized Solutions: We PLC programming services are carefully customized to align with the precise requirements of your individual machine or project, ensuring that each unique system operates at its best. Our engineers think outside the box to develop creative PLC automation strategies that competitors might miss.

- Seamless Implementation: Through exhaustive exploratory phases and a culture of close collaboration with our clients throughout the development process, we ensure that our programs integrate smoothly with any existing infrastructure. This approach minimizes downtime and maximizes productivity for your business.

- Rigorous QA Testing: We conduct thorough testing on every PLC program we build. Our team uses advanced tools and techniques to verify that your custom PLC programming is properly integrated and performs according to the system’s requirements. This helps ensure reliable operation in real-world conditions.

- Future-Proof Programming: Our relationship with you doesn’t end at delivery. We offer ongoing technical support to address any issues that may arise and keep your business running smoothly. We also provide scalable solutions that grow with your business. As your needs change and evolve, we’ll be there to help you adjust your system accordingly.

Improve Your Operational Efficiency with PLC Programming Services

Don’t let outdated or inefficient systems hold you back. PEKO is well-versed in custom PLC programming, and you can trust our team with all aspects, like program development, installation, testing, and troubleshooting. With our services, you can boost the potential of your manufacturing processes and better navigate the complexities of industrial automation for stronger, more efficient, and future-forward workflows. Contact us today to discuss your requirements and get started on your next project.