Metal powder coating is a dry finishing process that involves applying dry colored powder to a metal product via electrostatic means and melting it into a smooth, hardened, protective metal coating. It has become a preferred alternative to traditional metal finishing methods, such as wet spray painting.

This type of metal finishing works to enhance the final product’s quality, durability, and appearance. In addition to this, it is environmentally friendly and more cost-effective than other methods.

Advantages of Powder Coating for Steel Fabrication

- Provides a tougher, harder finish than traditional paint

- Resistant to corrosion, chemicals, and general wear

- Easier to produce think, even protective coatings

- Enhances the final products’ appearance

- Enables electrical conductivity/resistance

- Greater reflectivity, torque tolerance, and solderability

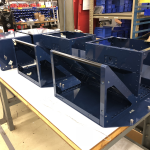

PEKO’s Onsite Powder Coating Capabilities

Over time, we’ve realized that paint can be a problem for everyone. Hours upon hours spent careful planning and coordinating to get to the final steps of an assembly can be altered by complications with paint which can make or break a deadline. This is why PEKO’s sheet metal division offers powder coating finishing.

Here, you will find our 10,000 sq. ft. powder coating paint line, which features a semi-automated powder coating system, including both paint booths and a line, as well as a GAT conveyorized powder coating line that operates for larger items that are unable to pass through our semi-automated powder coat line. Our powder coating services are available for all metal parts, components, and panels up to 5ft long and 9ft wide.

The Benefits of In-House Metal Finishing Services

Anyone in the world of manufacturing knows that outsourcing painting and finishing processes can cause bottleneck issues if not managed properly.

By integrating PEKO’s in-house metal finishing services, lead time and markup issues are avoided. If there are issues within our painting division, we can instantly make the adjustments necessary so that deadlines are met. Additionally, the ability to powder coat onsite allows for better quality control.

- Faster turnaround time and reduced lead times

- Better control in quality and throughput

- Consolidated supply chain

- Lower costs for powder coated parts

With PEKO as your powder coating provider, you can rest assured that your product will come out high-quality eye-catching finish that was done in-house with the care of the same people that built it.