Low-Volume Production Fabrication Services

When you need a sheet metal production partner for dozens, hundreds, or even a few thousand parts, look no further than PEKO!

We have the tools, technology, and people needed to fulfill your sheet metal production and fabrication requirements. Whether you’re in need of a bridge to higher volume repetitive flow production or small scheduled batch production of sheet metal parts, you can trust that your product will be built to order and delivered on schedule with PEKO as your partner.

- Full-service cutting, bending, forming, punching, and welding fabrication services.

- Sheet metal finishing, hardware installation, and mechanical assembly post-processing.

- Low-to-medium volume high mix cellular assembly and cleanroom environment areas.

Production Fabrication: Your One-Stop Shop

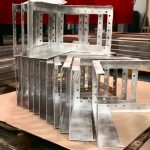

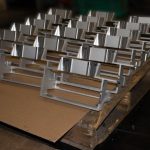

As a full-service contract fabricator, we can completely take over your entire low-volume production fabrication manufacturing operation, from start to finish. We offer a full suite of in-house precision sheet metal fabrication capabilities to provide everything you need, including forming, bending, laser cutting, punching, and welding, of carbon steel, stainless steel, and aluminum metal sheets up to 120” in length and ¾” material thickness. We typically work with low-volume production fabrication lot sizes ranging from 10 to 500 units per batch.

Post-Processing & Value-Added Services

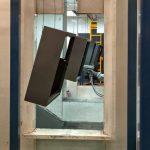

We can support various inspection requirements and provide secondary operations like powder coat finishing, wet painting, silk screening, hardware insertion, and mechanical sheet metal assembly. We can also provide sheet metal engineering, new product development, and turnkey low-volume high-mix assembly and integration services as needed.

From simple steel brackets and sheet metal fabricated parts to custom enclosures and fully integrated box builds, we’ve got you covered. Get in touch with us today about your production fabrication needs.