Contract Manufacturing & Engineering Capabilities

With over 50 years in the industry, PEKO knows a thing or two when it comes to contract manufacturing. We have been providing complete contract manufacturing services for premier OEM’s all over the world. With a focus on new and innovative technology, our engineering and manufacturing teams work together using our expansive contract manufacturing capabilities to create a full-service, customized process to replicate your complex equipment in our state-of-the-art facilities.

Even when your design still needs work or when you don’t even have anything on paper yet, that’s no problem. When you choose PEKO as your manufacturing partner, our engineering team is more than happy, and qualified, to assist you with the design and development of your project. Once you realize PEKO’s extensive in-house capabilities, you’ll be confident in our ability to keep the cost down and the lead time where it should be: on time!

Whether you’re a Fortune 500 corporation or a brand-new technology startup, you can count on PEKO to be your full-service contract manufacturer. With our extensive vertically-integrated contract manufacturing capabilities, we can provide you with the support that you need through the entire product lifecycle.

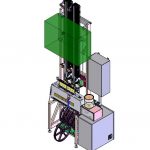

Complex Systems Integration

Our highly skilled technicians, engineers, and project managers have a thorough understanding of the capabilities and optimal methods for successful integration, allowing us to support even the most complex systems integration projects involving hundreds of combined subsystems and components within a single bill of materials (BOM).

Product Development Engineering

PEKO can work with you to refine and optimize your design into a repeatable, production-ready product. Leveraging our knowledge and experience in product development, we review your product for functionality, reliability, durability, manufacturability, ease of assembly, and more to help minimize processing problems, reduce cycle times, lower manufacturing costs, and accelerate your product’s time to market.

Program Management

Program management is one of our strongest attributes. Our program managers will oversee your program’s key cost, quality, and delivery metrics and work closely with your team to successfully lead your program through the entire product manufacturing cycle.

Small Parts CNC Machining

At our Rochester, NY facility, there are 25 CNC machines dedicated to our small parts services. These machines carry work envelopes of under 25 inches and are supported by an inspection/quality group with the latest in metrology technology.

Metal Powder Coating Finishing Services

PEKO’s in-house metal powder coating finishing provides the perfect final step for fabrication projects to increase their durability. Our 10,000 sq. ft. powder coating paint line is can handle all metal parts, components, and panels up to 5ft long and 9ft wide.

Precision Welding

PEKO’s precision welding services have the ability to handle large and complex welding projects that require an advanced level of quality and expertise. Our certified welders are capable of working within very tight tolerances to meet the most demanding application requirements. This specialized area is perfectly outfitted to fabricate welded frames, enclosures, and other assemblies.

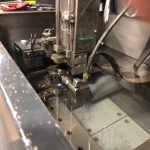

Machine Vision System Integration

PEKO has extensive experience integrating machine vision systems and can provide recommendations and troubleshooting based on the specific needs of your machinery.

Large Parts CNC Machining Services

Get Large Parts CNC Machining From PEKO Experience Unmatched Quality and Precision Choose PEKO for your large parts CNC machining needs. Our large parts machining department has garnered attention from some of the world’s leading manufacturers, and it is evident why. With the remarkable capability to manufacture tight tolerance parts exceeding 161” in length, PEKO […]

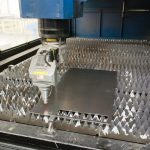

Sheet Metal Prototyping

For superior sheet metal prototyping services, PEKO is a partner you can rely on. Whether you need assistance testing the form, fit, and function of a new product or experimenting with a new manufacturing process, we are prepared to support your entire journey from prototype to production.

Supply Chain Management

Supply Chain Management for Contract Manufacturing Choosing PEKO as your Contract Manufacturing partner gives you access to our Supply Chain team. Often overlooked, having an experienced supply chain is very important to running a contract manufacturing program. Whether it’s a single CNC machined part, or a thousand-line BOM for a complex machinery series, PEKO supply […]

Industrial Wet Painting

PEKO offers in-house industrial wet painting services utilizing wet spray technology and customized paint booths for high-end applications. With our immense paint booth size, we can provide our industrial wet paint services for products of all shapes and sizes.

Manufacturing Inspection

PEKO’s vertically-integrated contract manufacturing services allow its engineering and manufacturing personnel to verify the quality of your product at various stages throughout the production process. Such streamlined inspection processes are extremely helpful in standardizing quality and increasing efficiencies across the board, in addition to preventing quality problems and supply chain disruptions down the road.

CAD Drafting

PEKO provides CAD drafting services as part of a comprehensive offering to develop machinery and equipment for commercialization. PEKO’s mechanical and electrical engineering teams are skilled at CAD modeling and will work with customer engineers to recommend design improvements for the CAD drafting process.

Production Readiness Review

A production readiness review is PEKO’s first step when accepting an order to build a new product. In this review, the focus is on engineering and manufacturability to lay the groundwork for a successful first-time build.

Technician Training

Because we are engaged with highly specialized and complex equipment, PEKO naturally places a great deal of emphasis on technician training. Maintaining a comprehensive training program ensures that technicians are properly educated on how to operate specialized machinery in a highly specific product manufacturing and testing environment.

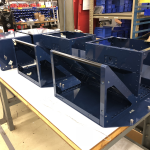

Contract Assembly & Subassembly Manufacturing

Our contract assembly and subassembly manufacturing specialize in turnkey systems and assemblies with difficult-to-produce geometries and close-tolerance designs. From simple subsystems to highly-complex electromechanical equipment with hundreds of parts, we have the capacity, equipment, staff, and processes to handle the job.

High Level Assembly Manufacturing

From simple box builds to highly complex electromechanical assemblies, we can manufacture and assemble a wide assortment of high-level assemblies per our customers’ requirements.

Electromechanical Assembly

PEKO offers low- to mid-volume contract manufacturing solutions for complex electromechanical assembly requirements, including subassemblies, higher level assemblies, and fully integrated top-level systems.

Bill of Materials & BOM Management

PEKO is well-versed in BOM validation and verification and can analyze customers BOMs and identify alternative options and sources that can help reduce costs, shorten lead times, and eliminate manufacturing disruptions. Furthermore, PEKO can implement your BOM in a way that ensures that they are accurate, current, complete, clear, and actionable.

Wire EDM Services

PEKO’s wire EDM services bring a tight tolerance capability that can be used on tooling, hard metals, and unique geometries. As a secondary offering for PEKO, we use these machines for customers that have precision assemblies with very high tolerance components.

Factory Acceptance Testing (FAT)

After assembly and integration commence, we perform final testing on each build’s design, components, subassemblies, and final completed units according to mutually established acceptance criteria. This ensures the utmost quality of each and every build before they ship from our facility.

Low Volume Production Fabrication

Whether you’re in need of a bridge to higher volume production or just small scheduled batches of sheet metal parts, you can be confident that your product will be built to order and delivered on schedule with PEKO as your partner.

Order Management and Fulfillment

Our contract manufacturing team has extensive processes to ensure order management and fulfillment take place on time. This lengthy process involves capturing orders, processing manufacturing operations, packaging, and delivering to customers.

Precision Component Manufacturing

Precision Component Manufacturing Over the past 55 years, PEKO has amassed a fleet of over 100 machines for both CNC machining and sheet metal fabrication. This important feature is paramount to our customers, whose contract manufacturing programs typically require high quality component parts integrated into their equipment. Unlike other CM’s, PEKO’s vertical integration of components […]

Precision CNC Machining Services

For decades, PEKO has mastered the ability to perform CNC machining of highly complex component parts that are used to build our assemblies and sub-assemblies.

Functional Requirements

Functional Requirements Development & Refinement In the product development stages of machinery manufacturing, PEKO engineers will review your functional requirements. Developing a deep understanding of how the equipment should work is an integral part of the new product development process. If a formal document does not exist, we will work with you to understand critical […]

Mechanical Engineering

PEKO offers a mechanical engineering services department specializing in machinery, equipment, and testing. The goal of the mechanical engineering services team is to ensure your project is given the best treatment so that functionality, cost, and manufacturability are all optimized and within spec. Whether it’s updating the CAD models, verifying a BOM, or creating a custom test fixture, PEKO is prepared.

Controls Engineering

Our controls engineers have experience integrating all types of machinery components, including PLCs, HMIs, industrial power supplies, motion control systems, vision systems, sensors, linear actuators, temperature control, data acquisition, and more.

Reverse Engineering

PEKO engineers are suited to reverse engineer machinery products that are fully owned by the OEM. Our engineering team is adept at understanding the functionality and manufacture of machines and equipment. Our engineers have the skills, equipment, and know-how to properly reverse engineer a machine.

Test Engineering

Our dedicated test engineering team assists in the creation of Final Acceptance Tests (FAT), Automated Test Equipment (ATE), product testing and verification plans, life testing, prototype development testing, and more.

Motion Control Systems Integration

PEKO has decades of experience installing, configuring, testing, and troubleshooting motion control systems for a variety of high-tech industrial applications. Our electricians and engineers will create processes to properly integrate motion control systems into your machinery and equipment.

Prototyping

Prototyping is our first step in evaluating functionality and determining critical parameters. Our engineers can handle even the most complex prototype requirements. This allows our team to thoroughly vet technology to validate proof-of-concept and reduce iterations before preparing for pilot builds.

Production Manufacturing

Production Manufacturing Time to ramp up! After the accomplishment of the development process is reached the next challenge is how to successfully scale to production manufacturing volumes. PEKO’s in-house resources are fully capable to absorb this increase in quantity. We have over 90 CNC’s onsite, full sheet metal capabilities, and versatile warehouse and floor space […]

Codes / Regulatory

Codes / Regulatory Support Compliance is the name of the game. Regulatory requirements and 3rd party agency approvals are one frequently a stumbling block for any development project; however these government regulated standards cannot be ignored. PEKO will successfully navigate customers through this often times, misunderstood territory. Engagement at an early stage is one key […]

Procurement Management

PEKO has an in-house procurement team who is responsible for managing all procurement activities on behalf of our customers, like sourcing for vendors, negotiating prices, estimating demand, placing orders, acquiring parts, handling paperwork, and more.

Packaging / Logistics

Packaging / Logistics Connecting to the end user. As a part of PEKO’s vertically integrated capabilities, we offer complete packaging solutions appropriate for each application. This includes the development of packaging designs and prints as well as any testing that may be required. PEKO provides direct drop shipments to many of our customers’ end-users and […]

Sheet Metal Forming & Bending

When it comes to metal forming and bending, you can trust us to provide the best solution for your needs.

Manufacturing Capacity Planning & Management

Creating a capacity management system that is flexible, dynamic, and can account for unforeseen shifts in demand is one of the most powerful service offerings. Our holistic manufacturing capacity planning helps maximize production goals and stay ahead of potential issues.

Life Cycle Testing

Life cycle testing, sometimes known as durability testing, reliability testing, or accelerated life cycle testing, is a method of product testing that simulates the life of the product in a dramatically shortened period of time. When you partner with PEKO to develop a new product in the machinery, equipment, or hardware category, we perform life […]

Linear Actuator Integration

PEKO helps integrate linear actuators into machines and electro-mechanical assemblies daily. Our engineering team can assist with selecting, installing, and testing linear actuators for a wide range of industrial systems.

Sheet Metal Laser Cutting

We have three advanced programmable high-speed lasers that can handle large sheet metal sizes, up to 60″ wide and 120″ long, and with a thickness of up to 0.75”.

Sheet Metal Finishing & Coating

We perform a range of sheet metal finishing processes, including powder coating, silk screening, and wet painting, to provide our customers with durable sheet metal products that withstand the most demanding applications and are protected from the harshest environments.

CNC Fixture Design

PEKO’s CNC machining division employs dedicated tooling engineers for its machining fixture design. In this area, we provide CNC fixture design for large and small machining centers, CNC milling and lathe machines with critical design tolerances.

Industrial Power Supply Integration

PEKO has the tools and processes necessary for integrating industrial power supplies into your machinery, equipment, or hardware. Our controls engineers will work with you to choose the right industrial power supplies for your system or order the make and model from your spec. We’ll then integrate, test, and troubleshoot them accordingly.

FMEA & Risk Assessment

PEKO has plenty of experience with failure mode and effects analysis and is happy to assist startups apply FMEA techniques to their new product development project. Our well-versed engineering team is capable of implementing Design FMEA (DFMEA), Functional FMEA, Process FMEA (PFMEA), and Manufacturing FMEA.

Sheet Metal Assembly

Our skilled technicians have mastered the art of sheet metal assembly and are prepared to tackle even your most challenging projects. Whether you require a comprehensive turnkey product, large-scale fabrication, precision assembly, or just a few component-level subassemblies, we’re equipped with all the tools needed to assemble dozens or even hundreds of parts into complete assemblies that satisfy all your requirements.

Design for Manufacturing & Assembly (DFMA)

At PEKO, our engineers consistently work on several different aspects of DFMA for a variety of our new product introduction and contract manufacturing projects. Our DFMA customers benefit from optimized designs, reduced costs, improved efficiencies, and long-term success of their program.

Manufacturing Control Plan

PEKO provides a manufacturing control plan for each and every part that runs through our CNC Machining and Sheet Metal Fabrication shops. This level of quality control helps ensure the highest quality integration when in both our Machinery Manufacturing and Precision Assemblies business units.

IP Protection & Security

PEKO does not have–nor do we desire to have–any products of our own. We perform all our contract manufacturing services in a comprehensive setting that provides extensive IP protection for all proprietary information that our customers provide to and/or produce with PEKO.

Product Testing & Verification

With our large inventory of advanced testing equipment and expansive repertoire of qualified engineers at our disposal, we are capable of performing a large range of standard and custom product testing procedures on a wide range of equipment and machinery.

Sheet Metal Welding

With a dedicated 10,000 ft2 facility, 20 welding stations, and over 140 internal WPS, we’re prepared to handle all your sheet metal welding needs, from large-scale pieces to intricate assemblies.

Manufacturing Documentation

Our team of engineers and production professionals will create a manufacturing documentation package to ensure the quality and repeatability of your build. This includes your BOM, detailed component drawings, quality control plans, manufacturing methods router, work instructions, FAT procedures, and packaging specs.

Value Engineering & Value Analysis

PEKO has extensive knowledge in design and manufacturing and a broad skillset across many value engineering techniques and best practices. With an “all hands on deck” approach, we involve other PEKO personnel who are directly involved in the program to offer their insight and additional feedback.

Metal Silk Screening

PEKO has mastered the metal silk screening process and can provide the highest quality prints to meet customer specifications. This ancillary service is suitable for a range of industrial applications, including screen consoles, control panels, racks, and more.

Fabrication Engineering & Sheet Metal DFM

Our experts leverage years of experience to review your design for manufacturing and pinpoint opportunities for increased efficiency, reduced manufacturing cost, and improved quality in sheet metal part fabrication.

Test Development Services

PEKO is your go-to partner for all your test development needs, including creating detailed test plans, designing custom test equipment, executing system and subsystem-level testing, and more.