Sophisticated Contract Manufacturing Made Simple

As you may know, the New England area–specifically Boston–has hundreds of machine/manufacturing shops, but what sets companies apart from one another? By attending trade shows you have the chance to get in front of innovative companies that utilize the newest and latest technological advancements. However, it’s easy to become sidetracked, or even overwhelmed, by a company’s flashy booth that isn’t a solution to your problem–especially if you are seeking a sophisticated contract manufacturer to manage the production of your product.

We recently published a post on The Essentials of a High-End Manufacturing Plant–which dives into the “must-sees” when touring a facility–but what should you be on the lookout for when strolling through the endless lines of booths at a trade show? As we prepare for our own booth for the D2P show in Marlborough, MA this month, we put together a quick overview for you to make the most of your next trade show.

Full-Service Manufacturing Partnerships

Fully Integrated Development Processes

Does the contract manufacturing firm have the capabilities to support and manage your product’s development through its entire process? For example, at PEKO our full range of capabilities flow through the following stages:

- Technical Specification

- Design Engineering

- Prototyping

- Quality Management

- Manufacturing

- Regulatory

- Procurement

- And Packaging

This allows us to provide our OEM customers with complete support through the entire developmental process from start to finish.

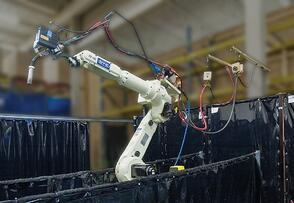

While visiting different booths at a show, be sure to ask if the CM can handle the management of your project in its entirety! Ask about their CNC machine capabilities and sizes. The fewer companies involved in the handling of production may remove unnecessary communication mishaps you’ll have to deal with in the long run.

Diverse Industry Backgrounds

If you’re seeking a contract manufacturing company to produce a highly complex, or sophisticated piece of machinery, then ask about the current industries the manufacturer currently works within. Equipment made for the Defense, Medical, Semiconductor and Energy industries can be rather tedious with intricate requirements during a product’s development. If you know that your project is complex enough to entail sophisticated requirements, make sure you feel comfortable with the manufacturer’s industry experience.