What are Industrial Machinery Manufacturing Companies Doing to Utilize the Latest Technologies?

If there is one thing I love to talk about, its new technologies being implemented by industrial machinery manufacturing companies.

This is a huge market that silently pushes the bounds of mechanical, electrical and software technologies. But since it is non-consumer, the masses typically are not exposed to such technology. For engineers, program managers, capital equipment stakeholders, and the like, these technologies can be game changers that shift the way we manufacture, test, design and inspect.

Today, we will take a look at some of the newest technologies that are coming through their lifecycle and permeating their way into the capital equipment manufacturing market. We will also look at similarities, differences, benefits, and risks of each.

Collaborative Robots (Cobots)

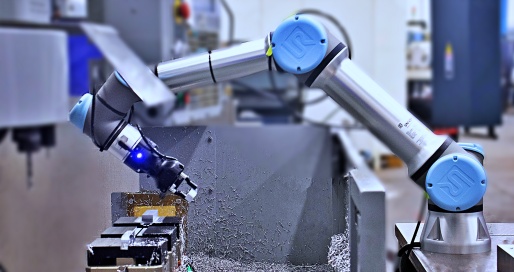

Right now, we’re seeing an increasing number of other industrial machinery manufacturing companies using cobots.

What is a cobot? A cobot is a collaborative robot, meaning that it can be installed and work alongside people, something that would be unheard of in the past. Their small size and slower speeds make them far safer than normal industrial robots.

Compared to industrial robots, cobots are easy to deploy, quick to program, and very portable. Cobots come with a price tag of roughly half of comparable sized traditional industrial robots. These robots can be ideal for shorter run programs or when a fully automated cell is not required. Cobots are manufactured by ABB, Universal Robots, Doosan, and quite a few more.

Here at PEKO, we’re now using cobots and have seen upwards of 400% efficiency gains in certain applications. Some criteria we use to determine if the cobot is a candidate for a specific CNC machining process is the volume of the parts run (longer is better), cycle time (shorter is typically better), and size (payload on our cobot is roughly 10 lbs.). Some other factors like geometry and complexity come into play as well because the robot needs to pick, load, unload, and pack.

The success of cobots in our industrial application will drive PEKO to invest in many more for the future.

Industrial Internet of Things (IoT)

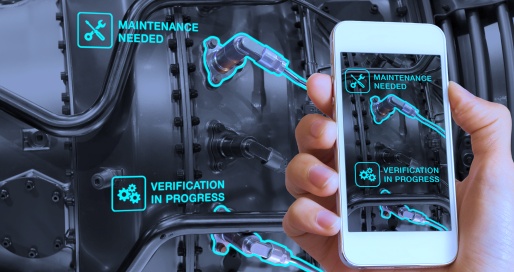

Whether it be for residential use or for commercial use, everyone is talking about IoT. The IoT, or Internet of Things, refers to the billions of devices all over the world that are using the internet to interconnect them.

An exciting part of this shift in technology is the impact that IoT has had (and will continue to have) on industrial machinery manufacturing companies and industry 4.0, also known as the Industrial Internet of Things (Industrial IoT).

I foresee two major uses:

- One will be the implementation of the technology for internal use, including applications like predictive maintenance, preventative maintenance, and even repair. Wouldn’t it be nice to be notified every time a machine bearing is showing signs of wear? It would be even nicer if the purchasing of said bearing was done for you automatically. Think about how many times your maintenance team has had to tear down a machine to troubleshoot. IoT technologies implemented with new and existing sensor hardware could change the way industrial machinery performs, is maintained, and the entire cost structure of owning capital equipment.

- Another idea is that Original Equipment Manufacturers (OEMs) and Contract Manufacturers (CMs) alike will be able to use IoT software and hardware to integrate into the equipment products they are building. Think about it… Straight from the factory floor, your new equipment will be all IoT ready with built-in features for maintenance and connectivity to your or your customers’ ERP, integrating with things like motors, drives, and sensors. With the Industrial IoT, new equipment will be machine learning, flexible manufacturing, and Industry 4.0 compliant right out of the box.

High Efficiency Electric Motors

With a surge in attention being given to industrial equipment manufacturing companies regarding climate change, companies like ABB are leading the charge to retrofit aging motors, drives and other industrial hardware with high-efficiency products.

To be fair, I had not even thought about the impact of aging industrial hardware on clean initiatives. In this Packaging Strategies article, it is stated that there are roughly 300 million motor-driven systems that may be underperforming electrically. This is an astonishing number and a huge opportunity for companies with environmentally conscious values to take advantage of energy savings and contribute to the clean push.

We can see this being a huge boom for the machinery manufacturing sector. Both Original Equipment Manufacturers and Contract Manufacturing companies can offer green solutions that are integrated into new and existing machinery.

Of course, this brings on many questions indeed. What will the payback be for a retrofit in the short term? What about the long term? How can capital equipment benefit from the performance of this technology? What are the tradeoffs in performance versus cost versus energy savings?

Like any new technology, there will be a health vetting process that involves stakeholder education, technology assessment, long term viability, and payback analysis. Combine this with the fact that more and more manufacturers of these systems will be racing to implement better and more competitive systems, and you could see a case where the high efficiency motor-driven system is the item of choice when designing and building industrial equipment 3 years down the road.

One other thing to consider is that it may not need to be just industrial equipment that makes the leap. Manufacturers of machinery for the medical, semiconductor, defense, and renewable energy industry all may have a place for these motors and drives in their own integrated systems.

We are experiencing new and exciting technologies every day that are pushing the envelope for industrial machinery manufacturing companies.

We are experiencing new and exciting technologies every day that are pushing the envelope for industrial machinery manufacturing companies.

Digital magazines, white papers, videos, and reports are readily available to help us determine which of these might fit our application and what types of benefits they will provide. We learn how to compare these solutions, calculate payback, and how to design them into our systems.

At PEKO, we are committed to staying at the forefront of these trends and helping OEMs determine how they can be applied to their industrial systems. For more information on choosing an industrial equipment contract manufacturing company, download our contract manufacturing checklist.