If you’re a renewable energy company looking for contract manufacturing of your machinery or equipment, odds are, you’ll want a vendor who offers CNC machining. Why, you ask? That’s because CNC machining is not only precise, but it’s also a much greener alternative to traditional manufacturing, producing a significantly lower carbon footprint. But when it comes to CNC machining for renewable energy, it is important to remember that not all contract manufacturing companies are created equal.

While CNC machines, like mills and lathes, are common across most machine shops, you may need specialty CNC services to get your renewable energy project to market on time and within budget. As you evaluate vendors for contract manufacturing of your clean energy machinery or equipment, here are four of the biggest CNC services you may want to take advantage of for your next project.

1. Rapid CNC Machining

When choosing a method of fabrication for your renewable energy project, there are a lot of factors to consider, like the requirements, materials, geometric features, and dimensional tolerances. But if you need to get your product to market quickly and want to reduce fabrication time with CNC machining, there’s another consideration: Rapid CNC Machining.

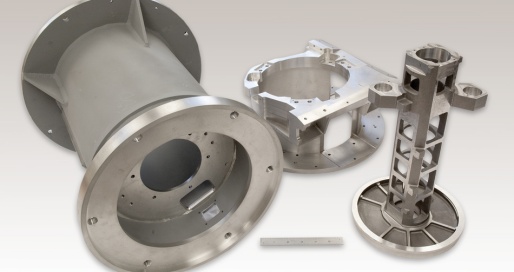

PEKO manufactures a variety of machined parts and components for major electromechanical builds and precision sub-assembly projects.

With rapid CNC machining, you’re able to make a precision prototype with either plastic or metal materials in a quick and cost-effective manner. A modern machine can take your 3D CAD files and raw materials and create a finished part in mere hours. Even an improvement or modification to the original design is fast and easy. As you research manufacturing vendors, be sure to ask about their rapid CNC machining capabilities if the turnaround time is crucial.

2. Assembly

Whether you’re launching new wind, solar, energy storage, or fuel cell technology, your renewable energy CNC machining project may require assembly work. If that’s the case, you may want to look for a vendor who offers turnkey management of complex assemblies, even for projects with multi-level BOMs and hundreds of parts. A one-stop, concept-to-completion approach can also help you save on production costs.

CNC machining of a large mechanical subassembly at PEKO.

So, if you need assembly, be sure to check if your potential contract manufacturing partners have the expertise, equipment, and technicians to run an assembly line for your project. Depending on if you need a stricter, climate-controlled environment, you may also want to inquire about their clean room assembly capabilities.

PEKO’s Engineering Manager, James Dawson explained, “For those customers who understand the value of outsourcing higher-level assemblies, PEKO’s turnkey products offering provides the answer.”

3. Finishing

While you may be satisfied with an “as machined” or “as milled” finish, there are lots of options when it comes to surface finishing for your CNC machined part. Finishing is the final step to improve a product’s appearance, provide additional strength, and add other features to the design. Common finishing techniques for CNC parts include steps like anodizing, powder coating, and bead blasting.

To ensure your final part has the desired characteristics, you’ll want to evaluate a contract manufacturers’ offerings when it comes to finishes and treatments. You may also want to see if they have the knowledge and expertise in-house to help you understand the additional processing that may be required and what’s best for your project.

4. Inspection

While intricate in-process control plans should be in place across a vendor’s fleet of CNC machinery, your renewable energy CNC machining project may have certain requirements for final inspection like validation testing to make sure the finished product matches the original design. For example, your fuel cell enclosure may need to be able to withstand 120 mph winds or a snow load of 2.9 kPa.

Since this step can be critical to your project’s success, be sure to find a partner that uses progressive techniques to produce parts that meet your demanding specifications. Some equipment and software that is typically used during the final quality control process include comparators, gage makers, coordinate measuring machines, and other precision measuring equipment and software. To ensure your project meets your needs, check on the quality competencies of any potential contract manufacturer.

Are you looking for a contract manufacturer? Download our checklist to find the right CNC machining partner for your renewable energy project.