Vast Engineering Experience & Manufacturing Resources

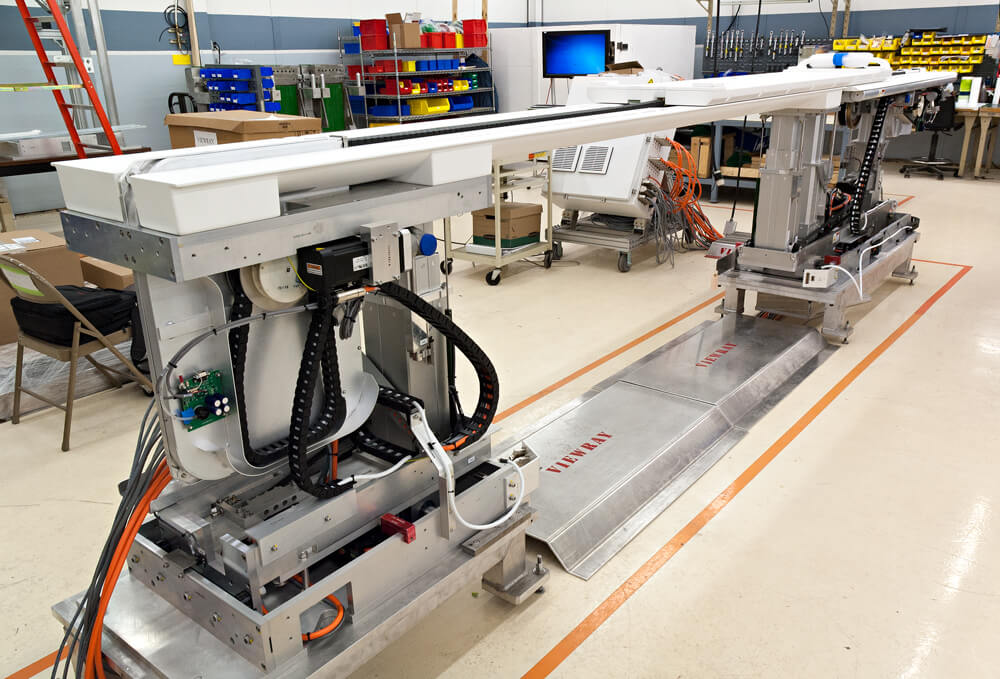

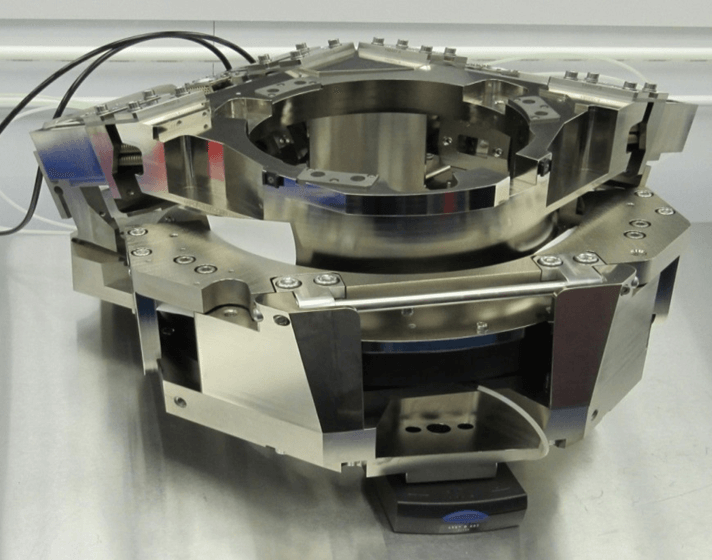

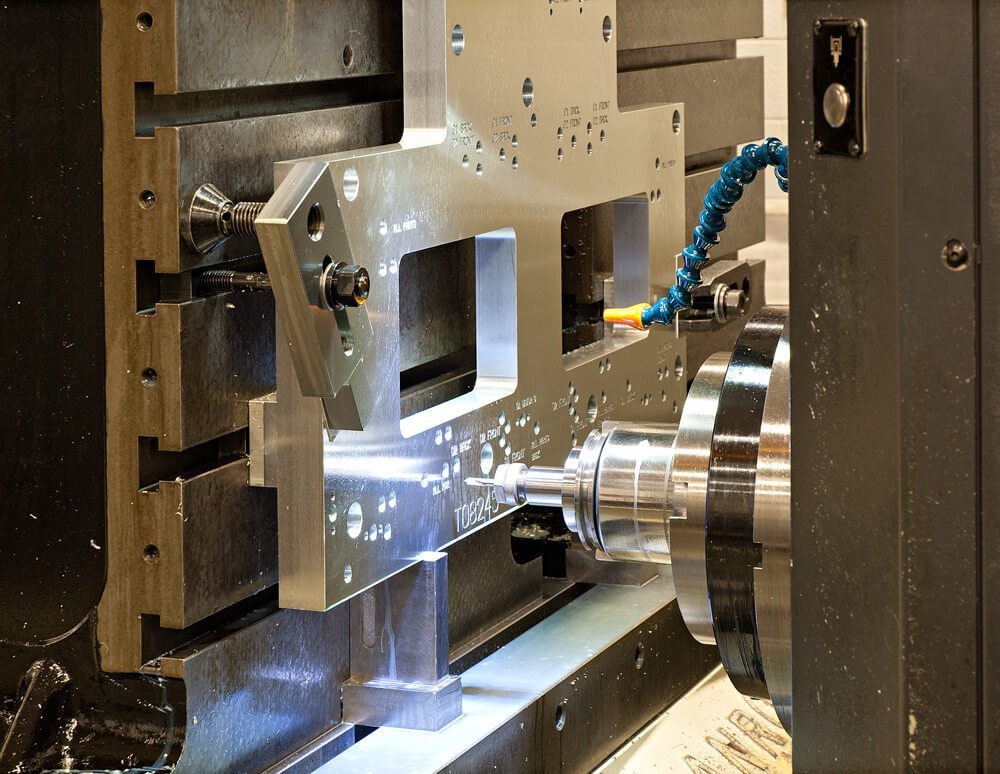

We have 30 engineers and Ph.D.s on staff across multiple engineering disciplines. Our extensive engineering staff combined with dedicated CNC equipment, tool room resources, machinists, electrical assembly technicians, and quality management systems are focused on quick-turn projects and process development with critical time-to-market deadlines.

PEKO’s flexible yet comprehensive industrial perspective allows us to effectively work with customers across all industries and sizes, including multi-billion-dollar corporations and early-stage startups. This range of customers also requires a diverse toolbox to reach the best solution for each emerging technology, innovative process, and product development.

PEKO’s range of development projects includes initial concept innovation for new technologies all the way up to enhanced next-generation designs for international portfolios.

Constant Evaluation of Price, Quality, & Delivery

PEKO has an extensive history in a diverse assortment of electromechanical systems and hardware new product development. PEKO’s foundation of developing and building specialized equipment adds an additional degree of experience and understanding of these key metrics. The development of complete manufacturing systems from a blank sheet requires engineering analysis of critical process parameters which cannot be ignored. This pedigree allows PEKO to anticipate the pitfalls that our customers may face. Each of our customers are technical experts in their own critical core science; however, they still require PEKO’s experienced engineering and abundant manufacturing resources to successfully manage all phases of the development cycle while not ignoring price, quality, or delivery.

Ensuring Success from Start to Finish

Leading the effort on every development project are dedicated project managers who work closely with our customers to ensure all aspects of projects are addressed and expectations are exceeded. All operations take place within our manufacturing campus in Rochester NY allowing for easy review of project status and complete control across each and every step.

Risk-Mitigated, Financially Independent Security

Additionally, PEKO delivers its capabilities in a comprehensive setting that protects and preserves YOUR intellectual property. PEKO is a risk-mitigated, financially independent company that passes this security on to its partners, ranging from early-stage startups to advanced technology developers.

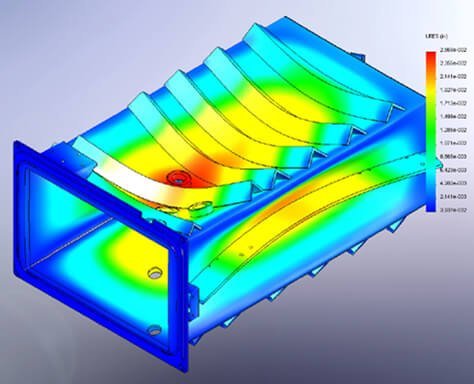

Data-Driven Solutions to Navigate Technical Hurdles

PEKO’s development engineering capabilities across multiple 3D CAD platforms and our long history in statistical-based testing and optimization efficiently take product concepts and process improvements through the commercialization process. This problem-solving philosophy is complimented by our expansive manufacturing facilities, which allows PEKO to partner with customers for long-term relationships throughout the life span of a product. We are able to collaborate with partners at every step in the development curve and successfully nurture an innovative solution, whether that is the development of a new product or a one-of-a-kind system for process automation and optimization.

PEKO’s Proprietary NPI Onboarding Process

New product introduction projects will go through PEKO’s proprietary onboarding process. This onboarding process is a case-by-case framework based on specific customers’ needs and the current state of the project that helps establish a strong foundation of critical parameters to execute their long-term goals. It includes one of the most critical steps in our operation.

Prior to defining a customer’s process, our top priority is to fully understand the customer’s needs and long-term objectives to develop milestone goals that will move the project through the product development cycle and into production. Because each customer has their own individualized needs and goals, this process will look different for each customer that works with us, and our NPI engineers are fully prepared to lay the groundwork for the first phase of your project.

Once a project reaches production, we are able to handle all aspects of contract manufacturing. Our engineering team works alongside our manufacturing and assembly teams, so you can rest assured that when your project has finished the onboarding process, it will be seamlessly transitioned to manufacturing, all while receiving excellent customer support.

NPI Onboarding at All Stages in the Development Cycle

Early-Stage Product Concepts & Feasibility

Sometimes, a customer comes through our door with only a concept or early-stage feasibility prototype and hasn’t truly vetted the technology yet. In these cases, PEKO will collaboratively engage with the customer and do a deep dive into the technology to ensure the critical parameters are fully understood and controlled, while simultaneously exploring the best approach to manufacturing. Our engineers are fully prepared to test a product’s functionality while gauging to what percentage it functions. This instance would still include development work from our engineering staff.

Pre-Production Prototypes & Pilot Builds

In other cases, customers will arrive at PEKO with clearly defined prints but have only had one or two machines built by a “small shop.” In these instances, PEKO engineers will work hard to make sure the prints can be brought to production readiness and support “scaled-up” production volumes when the time comes. This is to ensure exact repeatability is met when the equipment is introduced to a larger production climate. The methodology and approach taken to create one machine differs completely from what it takes to successfully create 10s to 100s of the same thing, with precise consistency.

Scaled Production & Product Maturity

Another instance is when a customer enters our doors with a product or technology that was manufactured by a third party, but unfortunately, the customer does not own the rights to the prints. Luckily for PEKO customers, all prints are the sole property of the customer. In these instances, PEKO engineers work diligently to reverse engineer the device so they can eventually create clearly defined prints.

50+ Years of Proven Product Development Success

With over 50 years of experience, PEKO has a proven track record of success in bringing customers’ designs to life, from engineering development and low-volume prototyping to full-scale manufacturing and assembly.

With over 50 years of experience, PEKO has a proven track record of success in bringing customers’ designs to life, from engineering development and low-volume prototyping to full-scale manufacturing and assembly.

We have completed development projects for customers of all sizes, from small businesses to Fortune 500 companies, and across many industries.

Some of the projects we’ve nurtured through the product development cycle include:

These projects were taken from initial product development to full-blown production volume contract manufacturing, including regulatory review and certification.

Contact us today to learn more about our services and how we can help you bring your vision to life.

Submit Project Details

With over 50 years of experience, PEKO has a proven track record of success in bringing customers’ designs to life, from engineering development and low-volume prototyping to full-scale manufacturing and assembly.

With over 50 years of experience, PEKO has a proven track record of success in bringing customers’ designs to life, from engineering development and low-volume prototyping to full-scale manufacturing and assembly.